What is pad printing ?

Pad printing is an indirect marking technic allowing to print any type of media, in any shape (concave, convex, flat) and any material.

Whether the machine is manual or automatic, technic is the same: a silicone pad picks up ink contained in the hollow parts of a plate and transfers it onto the object

Flexible and waterproof, the pad releases complete ink amount.

Cliché with artwork to print is obtained by reproduction of a typon on a plate that is etched to create hollows.

Pad printing is widely used for its sharpness and rapidity in automotive, watch making or electronics industries, for promotional items ...

our range of pad printing equipment

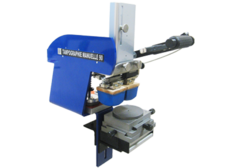

1 colour hand operated pad printing machine (90 mm ink cup )

Hand operated pad printing machine with 90 mm sealed ink cup for prints of diam 80 mm maxi.

Easy to use and economical , it allows the same results as with an automatic machine

2 colour hand operated pad printing machine (65 mm ink cups)

Same design as 1 colour machine, but 2 color version with 2 ink cups of 65 mm

A hand operated shuttle moves pads upon object to print the 2nd color.

Universal 90 - 1 colour pad printing machine (90 mm inkcup)

Semi automatic 1 color pad printing machine featuring

- 90 mm steel ring inkcup

- XY table to set print position

Universal 120 - 1 colour pad printing machine (120 mm inkcup)

Semi automatic 1 colour pad printing machine featuring

- 120 mm steel ring inkcup

- XY table to set print position

Universal 200 - 2 colour pad printing machine (90 mm ink cups)

Semi automatic pad printing machine including

2 steel ring ink cups of 90 mm

a 2 position pad shuttle

1 XY table to set print position

Universal 200 Ci - 2 colour pad printing machine (90 mm ink cups) with independent pad cylinders

Semi automatic pad printing machine including

- 2 steel ring ink cups of 90 mm

- a 2 position pad shuttle with independent cylinders, to print the 2nd color

- 1 XY table to set print position

TTN 100 EKO SERIES - TTN90 EKO TE 1 colour pad printing machine - sealed ink cup

Semi automatic 1 color pad printing machine with 90 mm ceramic ring inkcup

TTN 100 EKO SERIES - TTN 120 EKO 2 TC - 2 colour pad printing machine - sealed ink cups

Semi automatic 2 color pad printing machine including 2 ceramic ring closed ink cup of 65 mm + shuttle

TTN 100 SERIES - 1 or 2 colour pad printing machines - open ink cup

Semi automatic pad printing machine that can be supplied

- in 1 colour with 100 x 100 mm open ink cup

- in 1 colour with 100 x 120 mm open ink cup

- in 2 colours with 100 x 120 mm open ink cup

TTN 200 EKO SERIES 1 to 4 colour pad printing machines - Sealed ink cup

Semi automatic pad printing machine that can be supplied

- in 1 colour with 190 x 90 mm oval ink cup

- in 2 colours with 90 mm ink cups

- in 3 colours with 90 mm ink cups

- in 4 colours with 65 mm ink cups

TTN 200 EKO SERIES 1 to 3 colour pad printing machines - Open ink cup

Semi automatic pad printing machine that can be supplied in 1, 2 or 3 colours with several printing sizes.

TTN 350 EKO SERIES - 2 to 6 colour pad printing machines - sealed ink cups

Semi automatic pad printing machine that can be supplied

- in 2 colours ( 190 x 90 mm oval ink cup)

- in 3 colours (120 mm ink cups)

- in 4 colours (90 mm or 120 mm ink cups)

- in 5 colours (90 mm ink cups)

- in 6 colours (90 mm ink cups)

TTN 350 SERIES - 4 to 6 colour pad printing machines - open ink cup

Semi automatic pad printing machine that can be supplied in 4, 5 or 6 colours, with several printing sizes

UV MARK uv exposure unit

UV unit for exposure of pad printing cliche up to 255 x 305 mm.

UV Mark GF Exposure unit

UV unit for exposure of pad printing cliche up to 550 x 350 mm.

Automatic machine for cliche processing

Combined machine for automatic production of water processed plates ((exposure / development / drying)

maximum size = A 4 (210 x 297 mm).

Cliches and developer for pad printing

We can offer a large range of cliches: alcohol processed, water processed, steel etched or laser engraved cliches.

All are available in several sizes , for our own equipment as well as other machines.

Pad printing inks

As a partner of Printcolor Swiss company, we can offer a wide range of inks to suit printed substrate requirements

Pad printing silicon pads

Wide choice of silicone pads : shape, hardness or durability... suitable for any model of pad printing machine.

1 or 2 component fixing paste

Used to easily create a jig holding the parts to print.

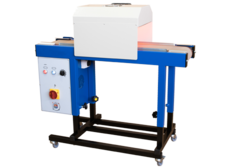

Infra red drying tunnel

Our infra red tunnels accelerate ink drying by evaporation of solvents.

They are available in several widths and lengths

Corona treatment for pad printing

Corona treatment consists of an electric discharge that will transform the material state and make it permeable to inks.

It is necessary for some plastics with a poor surface tension.

cleaning machine for pad printing ink cups and accessories

On the same principle of a washing machine, it cleans all pad printing elements in contact with ink : ink cups, spatulas, doctor blades...

Pad printing advantages & drawbacks

Pad printing offers many advantages, as it is possible to print

- on irregularly shaped media as the silicone pad closely follows the object shape

- on almost every kind of material thanks to a large range of inks

- small series as well as larger ones

- several colors without intermediate drying

Drawbacks can be

- A too thin ink layer if the cliché is not properly etched (not deep enough)

- Reduced printing sizes (in accordance with ink cup sizes)

- Important dyring time with some materials (that can be greatly reduced using an oven)-